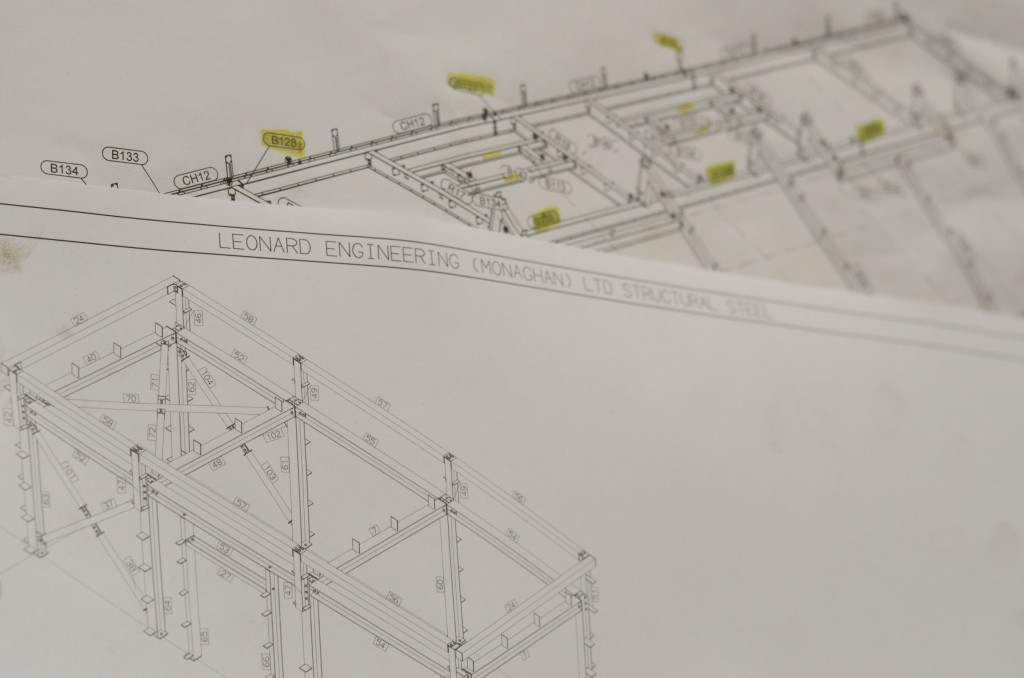

Steel Detailing

As fabrication drawings are a critical part of the steel fabrication process, all steel detailing is done in-house by experienced detailers using Tekla and Strucad software, both of which are linked directly to fabrication machines to enable speedy transfer of information and eliminate possible error. Our detailers work closely with architects and engineers to ensure that the end product is exactly what the client requires.

Shot Blasting

Shot blasting takes place in-house as surface preparation is critical to good painting. A regime of continuous inspection and checking of surface profile is carried out to ensure consistency. Surface preparation is carried out to a minimum of S.A. 2½ or greater if required.

Steel Fabrication

All fabrication is carried out to the highest standards by experienced fabricators. As all components are produced by automated machines that are programmed directly from the drawing office, a very high standard of accuracy is achieved. This coupled with welders that are coded to the relevant standards and a process of weld inspection by our Responsible Welding Co-ordinator ensures that only steel of the highest quality is produced.

Painting

All painting takes place in our purpose built paint shop that is fully equipped with fume extraction and material handling systems as well as temperature control. The following is checked and recorded on a continuous basis: relative humidity, air temperature, surface temperature and paint thickness. This along with excellent shot blasting ensures high quality paintwork is achieved.

Transportation

Leonard Steel has its own Volvo truck and a fleet of trailers including trombone for delivery of steel to sites. We also use a contracted haulage company when the need arises. Having our own truck and trailers gives the company flexibility to ensure deliveries are promptly made to sites.

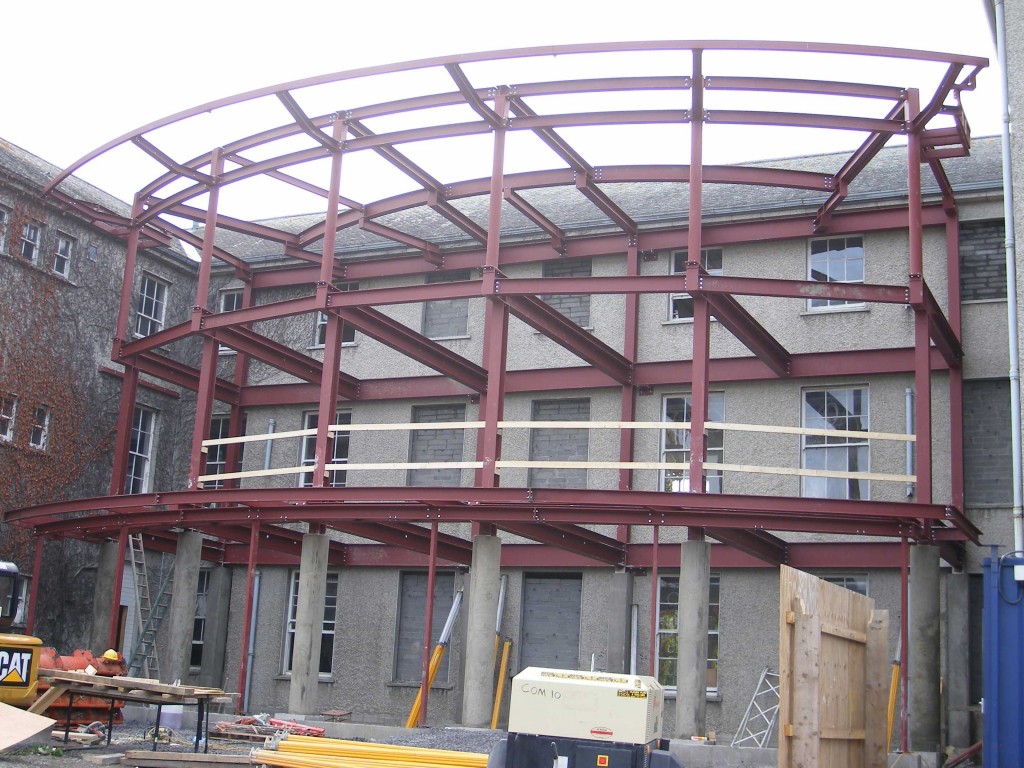

Steel Erection

Steel erection is critical to achieving the best possible end product for the client as it is the last piece in the jigsaw. The company uses only experienced steel erectors that are fully compliant with the latest safety codes of practice and are fully trained and certified.